It's been a couple of months since my last entry about this bookcase. I have been juggling several other projects but I must say that working in quarter sawn oak has proven to slow down the pace of everything. I'm also at a disadvantage because I drew a half scale drawing because of the size of the piece. I usually hand draw full scale drawings with all joinery worked out in advance of making anything. I made the drawing for the client to see and understand the design and I have been making the thing based on the principles of traditional joinery and generally doubling all the dimensions. This has proven to be a problem when it comes to the geometry of the opening of the center door and whether or not it hits the nice pulls that I bought from an English supplier. The projection of the center section neeeded to be considered and the small spacers between the cases had to be adjusted to best deal with the problem. If you study breakfront bookcases they nearly all open doors with a key, not a pull. I have dovetailed and glued all the cases, made all the doors, installed the doors and made the plinth. I've also drilled over 500 shelf holes by hand and partly inlaid the shelf supports into the shelves. I'll explain the images below.

Glueing up the lower cases.

A simple jig that I made to drill holes for the shelf pins. The hardware is really nice and stout but I had to be really careful not to drill through the sides because there wasn't much clearance. Note that the inside of the panels are flush with the frames so that the books can easily slide in and out without damaging them.

This shows the six cases with the doors attached but no plinth, waist moldings or cornice. I also plan to mold the leading edge of the shelves.

Part way through dovetailing the back of the base.

The back of the base dovetailed to the side of the base.

The proper way to glue the miters in the front of the base. I've glued the off cuts to the sides of the base to clamp them tight. Once dry, you cut them off and plane them clean.

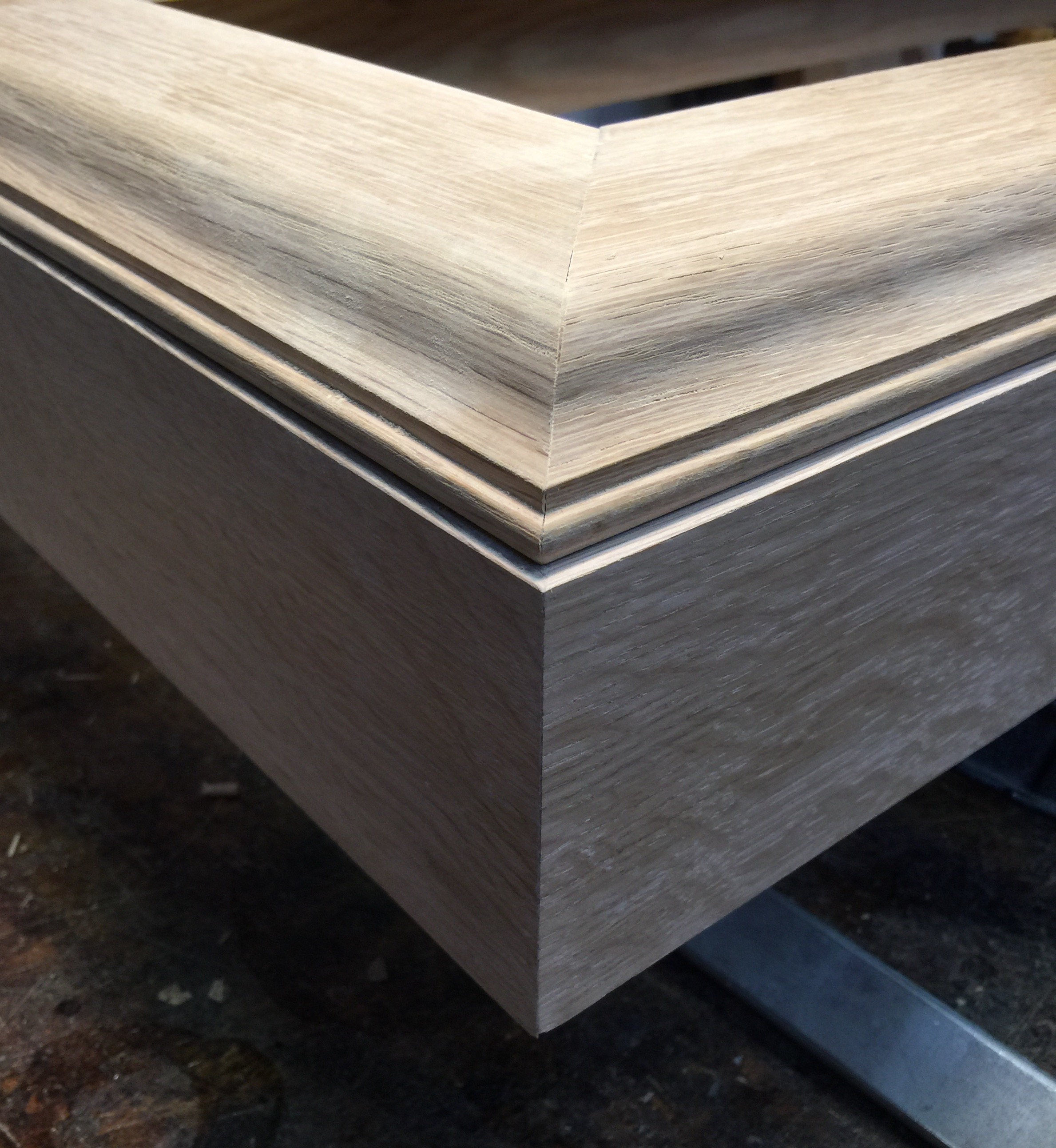

I made an ogee molding with a fillet sitting on a half round shape right out of Thomas Chippendale's Director. I had to make most of this molding by hand.

The right hand corner detail of the base cabinets on the plinth.

Lower section on the plinth awaiting the waist moldings. I will make them slide out to the left and right side like a bureau plat. They will be asupport some books or occasionally a small flat screen tv, which the client wanted.